Achieving Carbon Neutrality with Brother’s PLC-Direct Printing Solutions

In the modern era, sustainability and cost-efficiency are paramount for factories striving to maintain a competitive edge. One innovative approach to achieving these goals is through direct printing from PLC (Programmable Logic Controller) systems. Traditionally, factories have relied on PCs to print from PLC data, but this method not only incurs additional costs but also contributes to carbon emissions. Brother has revolutionised this process by enabling direct printing from PLCs, eliminating the need for a PC and bringing the significant benefits to the factory floor.

The Conventional Approach: Printing from PLC via PC

Typically, factories connect PLCs to PCs to handle printing tasks. While functional, this setup has several drawbacks.

Increased Costs:

The need for additional PCs adds to both initial investment and ongoing maintenance expenses. Additionally, purchasing label design software can further increase the costs

Higher Carbon Footprint:

PCs consume significant power, contributing to higher energy usage and carbon emissions.

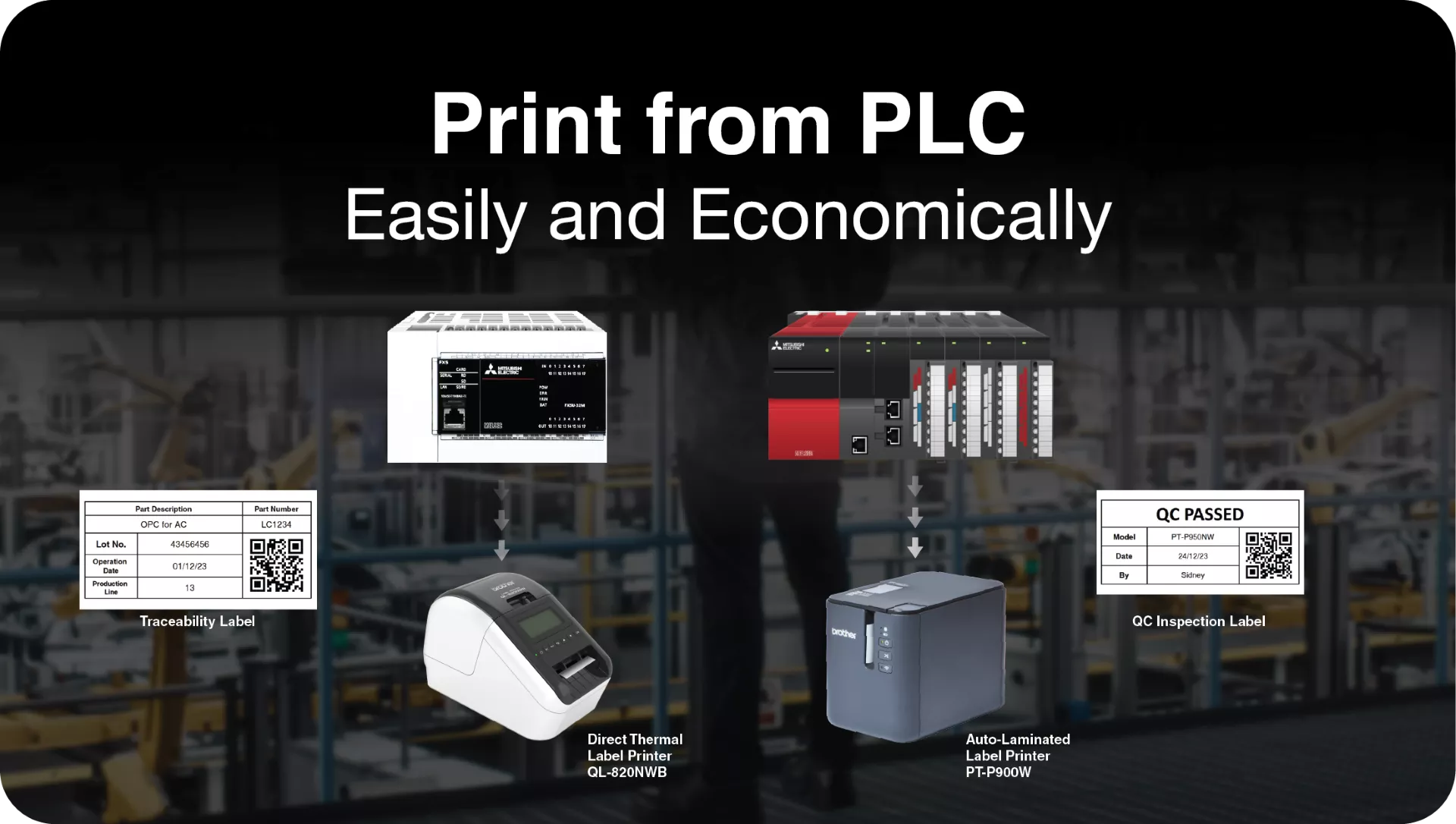

Brother’s Innovative Solution: Direct Printing from PLC

Brother’s direct printing solution allows factories to print directly from PLCs, bypassing the need for PCs entirely. This approach offers several advantages.

Cost Savings

By eliminating the need for PCs, factories can save on hardware costs, reduce energy consumption, and lower maintenance expenses. Additionally, while many label design software options come with substantial costs, Brother’s P-touch Editor is available free of charge. This not only reduces the initial setup cost but also provides ongoing financial relief.

Reduced Carbon Footprint

PCs are significant power consumers. By removing them from the printing equation, Brother’s solution helps factories reduce their overall energy consumption and carbon emissions, supporting sustainability goals and contributing to a greener planet.

User-Friendly Label Design Software

Brother’s P-touch Editor is a user-friendly software that makes it easy to create and customise labels. The fact that it is available free of charge adds to the overall cost-effectiveness of Brother’s solution, making it accessible without the burden of additional software costs.

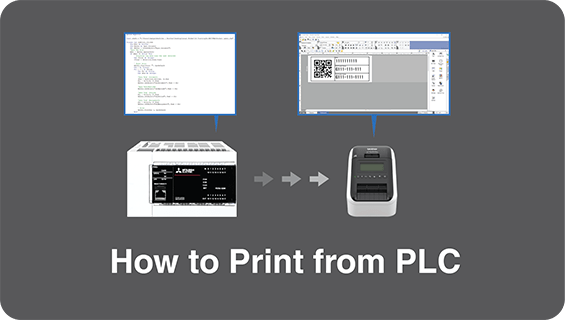

Efficient System Setup with Mitsubishi Electric PLC Integration

Brother provides sample programs for Mitsubishi Electric PLCs, drastically reducing the development time required for system setup. These pre-designed programs facilitate quick and easy integration, allowing factory managers to focus on other essential tasks without worrying about prolonged setup times. The integration with Mitsubishi Electric PLCs showcases the practical benefits of Brother’s solution, including time savings, cost efficiency, and reduced environmental impact.

Conclusion: Embracing Sustainability and Efficiency

Brother’s direct printing from PLC technology helps factories reduce costs and achieve carbon neutrality. By eliminating the need for PCs, this solution offers significant financial and environmental benefits. Factories can streamline operations, lower their carbon footprints, and contribute to a more sustainable future. Embrace the future of factory printing with Brother’s innovative solutions and take a step towards a greener and more efficient operation.