Enhancing Quality Assurance with Brother's

Label Printing Solutions for Automatic Inspection

In modern factory settings, ensuring accurate quality assurance (QA) is crucial in maintaining high standards of production. Traditionally, many factories still rely on manual methods for dimension measurement and labelling, which can lead to errors or even intentional cheating. As the industry moves towards more automated and efficient processes, the integration of automatic inspection and label printing solutions becomes imperative.

The Challenge with Manual QA Processes

Manual QA processes, where dimensions are measured by hand and labels are stamped with a "Pass" mark, pose significant risks.

Human Error:

Mismeasurement can occur unintentionally due to fatigue, distraction, or simple mistakes.

Intentional Misreporting:

There is always a possibility of intentional cheating, which can compromise the entire production line's integrity.

Efficiency Issues:

Manual processes are time-consuming, reducing the overall production efficiency and throughput.

These challenges highlight the need for an automated system that can ensure accurate and reliable QA while improving operational efficiency.

The Benefits of Automated Inspection Solutions

Automated inspection systems use advanced technologies like machine vision, laser measurement, and sensors to accurately measure product dimensions. These systems offer several advantages.

Precision and Consistency:

Automated systems eliminate the variability of human measurement, providing consistent and precise data.

Speed:

Automated inspections are much faster than manual checks, allowing for higher throughput and efficiency.

Reliability:

Automation reduces the risk of intentional cheating and human error, ensuring that only products meeting the quality standards are approved.

Integration with Automatic Label Printing

Combining automated inspection with automatic label printing creates a seamless QA process. Here’s how it works:

Automated Measurement:

As products move along the production line, automated inspection systems measure their dimensions at real-time.

Data Processing:

The measured data is instantly analysed to determine if the product meets the required specifications.

Label Printing:

For products that pass the inspection, an automatic label printer generates labels containing essential information such as the production time, production line details, and a "Pass" mark.

Enhancing Traceability and Efficiency with Brother's Solutions

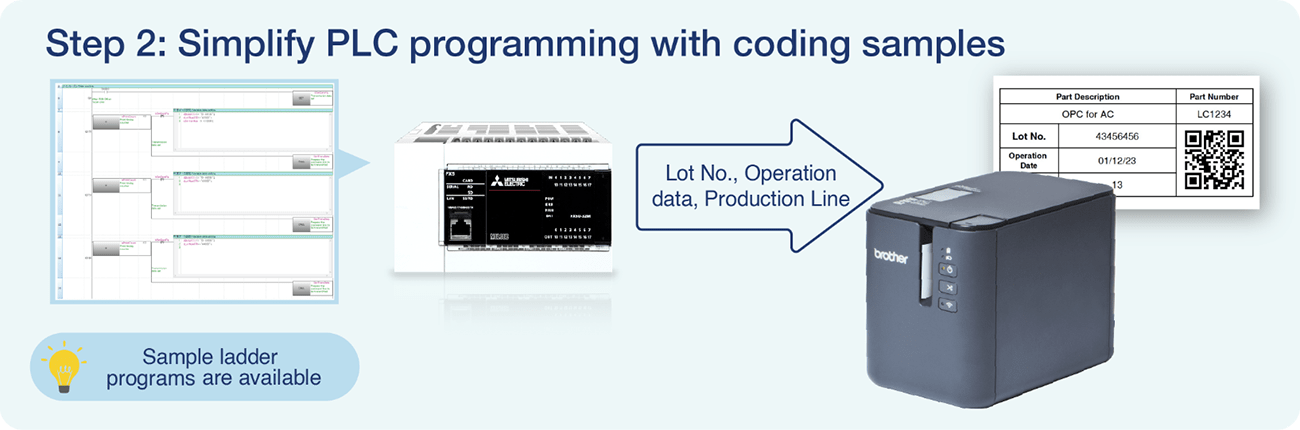

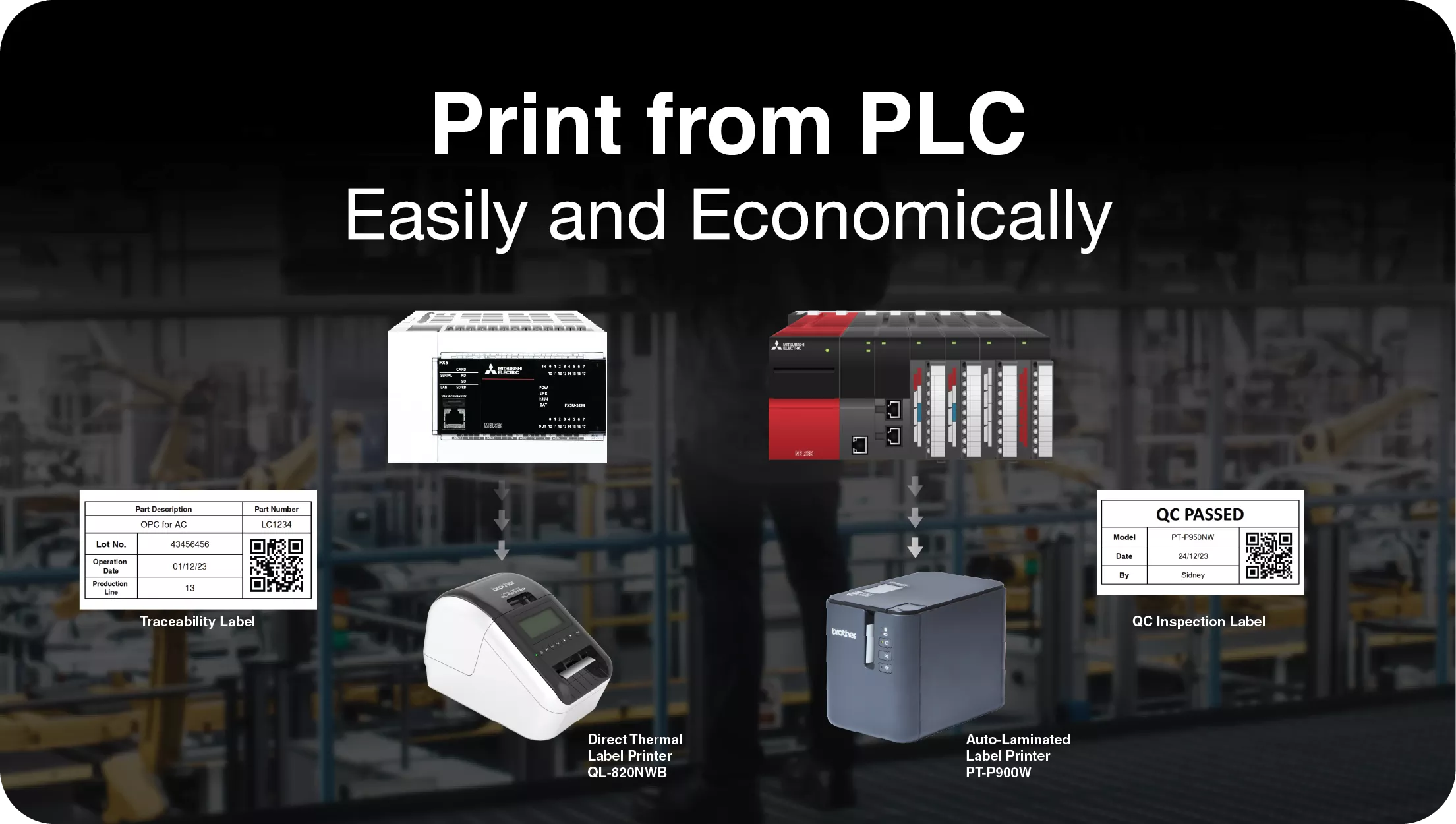

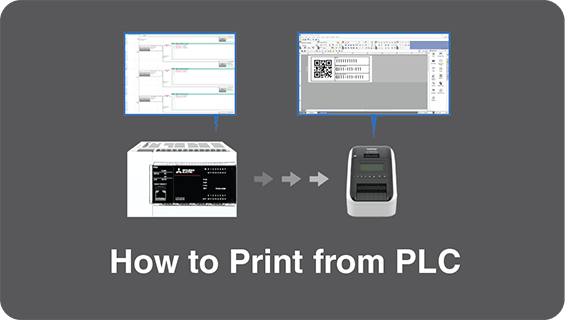

By connecting the automatic inspection and label printing system with a Programmable Logic Controller (PLC), factories can enhance traceability and efficiency. Brother offers a range of solutions that make this integration seamless and economical.

Sample Program for Mitsubishi Electric PLC:

Brother provides a sample program specifically designed for Mitsubishi Electric PLCs. This ensures easy and efficient integration with your existing production line, facilitating real-time data exchange and system control.

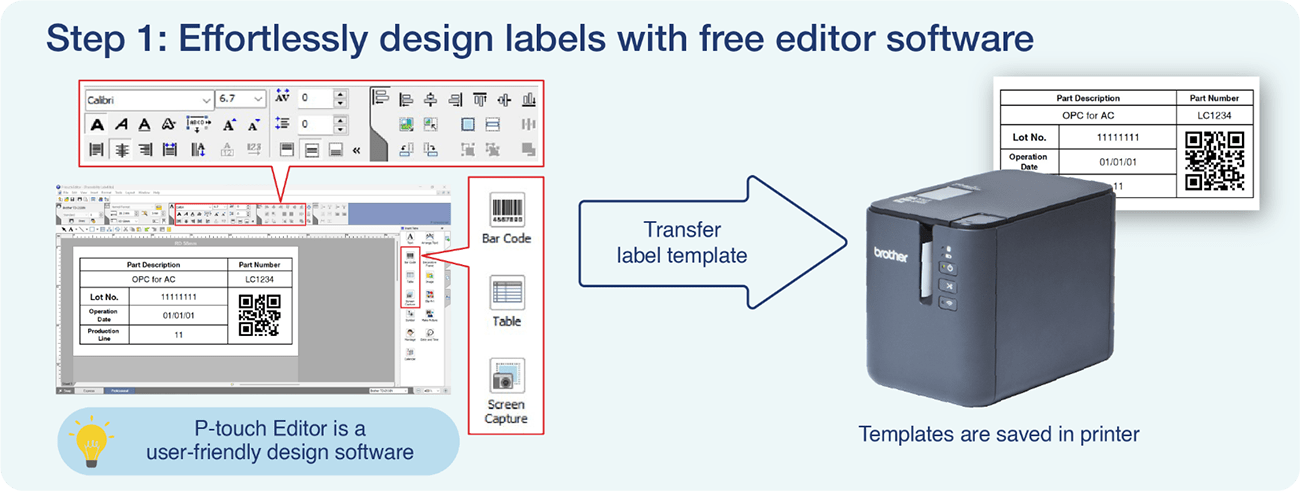

Easy-to-Use Label Design Software:

Brother’s P-touch Editor, available free of charge, is an intuitive label design software. It allows users to create customised labels quickly and easily, ensuring that all necessary information is included and clearly displayed on each product.

Key Benefits of Brother’s Solutions

Cost-Effective Integration:

Brother’s sample program and free label design software make it economical to implement automated inspection and labelling in your factory.

User-Friendly Design Tools:

P-touch Editor simplifies the label design process, allowing for quick adjustments and customisations without the need for specialised training.

Enhanced Traceability:

With detailed labels that include production time, line information, and QA status, you can achieve full traceability and quickly address any post-production issues.

Conclusion

Automating the QA process with integrated inspection and label printing solutions is a game-changer for factory settings. It ensures accurate, reliable, and efficient QA, enhances traceability, and boosts overall production efficiency. Brother’s advanced label printing solutions, coupled with our easy-to-use software and sample PLC programs, make this transition smooth and cost-effective.

By embracing these technologies, factories can not only improve their QA processes but also align with principles like Kaizen, driving continuous improvement and operational excellence.