How Brother's P-touch Editor Can Improve Factory Operations

In the fast-paced environment of modern factories, efficiency and organisation are key to maintaining high productivity and safety standards. One tool that can significantly contribute to these goals is Brother’s P-touch Editor. This powerful software, when paired with Brother’s range of label printers, offers a myriad of features designed to streamline factory operations. Here’s how:

1. User-friendly Interface and Accessibility

The software interface is similar to Microsoft Office applications, such as PowerPoint. This familiarity allows users to design labels with ease, using a toolset they are likely already comfortable with. Access a wide range of design tools and features that are straightforward and easy to use, minimising the learning curve and maximising the productivity toolset they are likely already comfortable with.

2. Enhanced Label Customisation

Brother's P-touch Editor provides extensive customisation options which allow factories to create labels tailored to their specific needs.

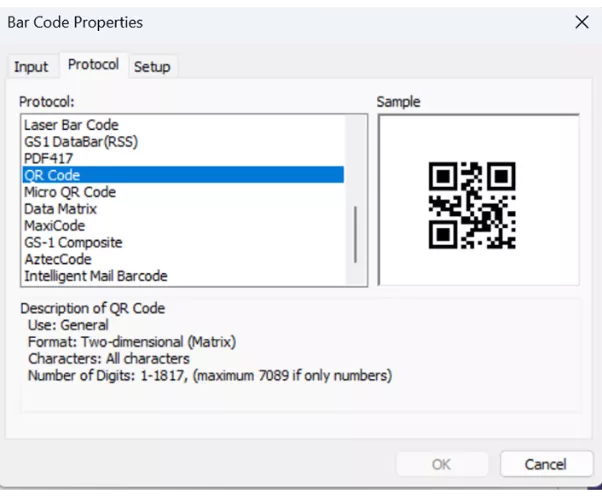

Barcodes and QR Codes:

Generate various barcode and QR code formats for tracking inventory, equipment, and products.

Graphics and Logos:

Incorporate company logos, graphics, and other images to create professional and branded labels.

Font and Text Options:

Choose from a wide range of fonts and text styles to ensure labels are clear and easily readable.

3. Streamlined Workflow Integration

Integrating label creation into existing workflows is seamless with Brother's P-touch Editor.

Templates:

Create and save label templates for different applications, ensuring consistency and speed in label production.

Database Connectivity:

Import data directly from databases to generate labels, reducing manual entry errors and saving time.