Enhancing 5S with Brother Label Solutions: Kaizen Approach

Implementing the 5S methodology - Sort, Set in order, Shine, Standardise, and Sustain - is crucial for achieving operational excellence in factory settings. However, common issues such as unreadable handwritten labels and weak adhesive labels often undermine these efforts. Brother’s laminated labels and P-touch Editor software present a robust solution to these challenges, aligning perfectly with the Kaizen philosophy of continuous improvement.

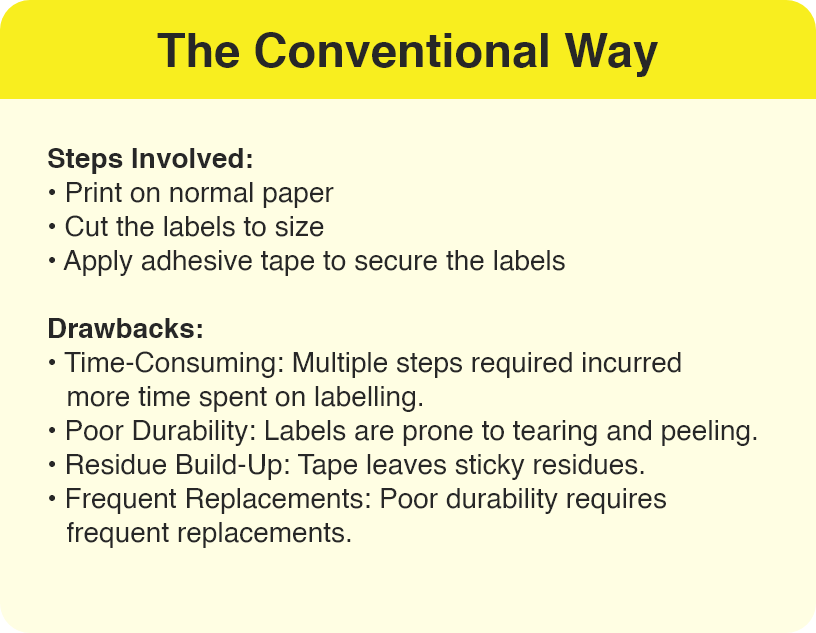

The Problem with Conventional Labels

Conventional labelling methods often involve printing on paper and using adhesive tape for securing the labels. This approach is fraught with issues.

Multiple Steps:

Printing on normal paper, cutting the labels, and then securing them with adhesive tape is time-consuming and labour-intensive.

Poor Durability:

Paper labels covered with adhesive tape do not withstand the demanding conditions of a factory floor. They are prone to tearing, fading and peeling.

Residue Build-up:

Adhesive tape leaves sticky residues when removed, which accumulate over time, creating a dirty and unattractive workspace.

These problems hinder the efficiency and effectiveness of 5S implementation, making it difficult to maintain an organised and productive workspace.

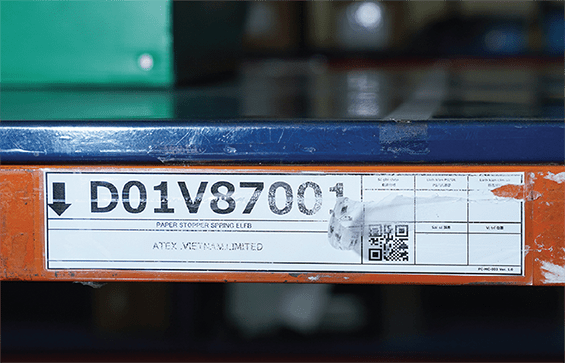

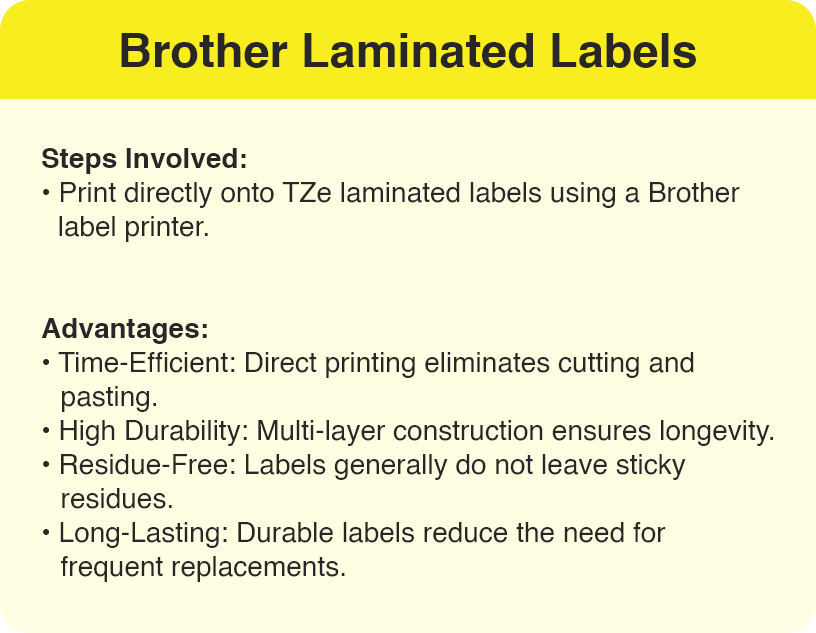

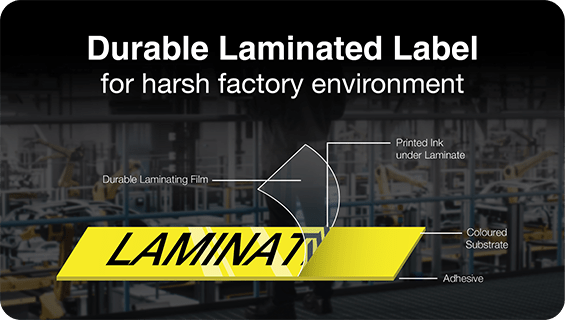

Brother's Laminated Labels: Durable and Reliable

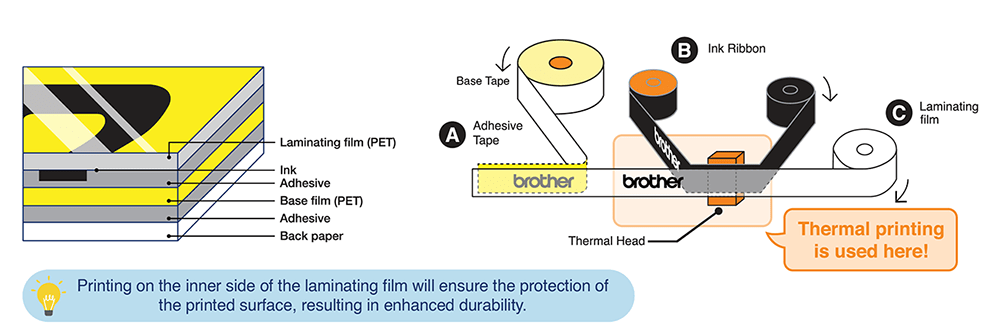

Our TZe laminated tapes, a hallmark of Brother's innovation, consist of six meticulously engineered layers. This multi-layered construction results in labels that are both thin and extraordinarily strong. At the core of our TZe tapes is a layer of thermal transfer ink, which forms the characters on the label. This ink layer is expertly sandwiched between two protective layers of PET (Polyethylene terephthalate), providing unmatched protection.

Chemical Resistance:

TZe laminated labels resist damage from various chemicals, maintaining print quality even when exposed to solvents and industrial cleaners.

Temperature Resilience:

These labels can endure extreme temperatures ranging from -80°C to 150°C, making them suitable for diverse industrial applications.

Abrasion Resistance:

The laminated surface of the labels can withstand significant abrasion without compromising the readability of the text, ensuring longevity in a busy factory setting.

No Residue in Most Cases:

Unlike regular adhesive tape, Brother’s TZe laminated labels do not leave sticky residues when removed, keeping the workspace clean and reducing maintenance efforts.

The Conventional Way vs. Brother Laminated Labels

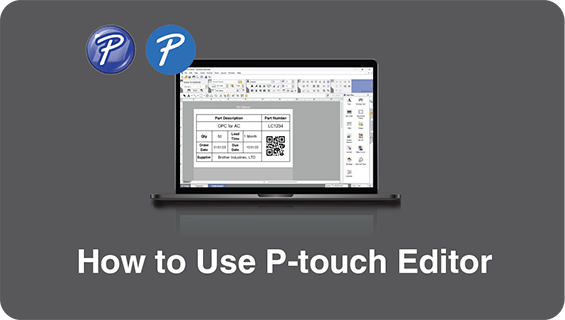

Easy Label Creation with P-touch Editor

Creating professional, customised labels has never been easier, thanks to Brother’s P-touch Editor software. This powerful tool enhances productivity and ensures consistency in label production.

User-Friendly Interface:

P-touch Editor features an interface similar to Microsoft Office applications, making it intuitive and easy to use. Users can quickly design labels using familiar tools, minimising the learning curve.

Streamlined Workflow Integration with Database Connectivity:

1. Database Integration:

P-touch Editor connects directly to databases, significantly reducing the time required for label creation.

2. Batch Printing:

Importing data from databases allows for the printing of multiple labels at once, increasing the efficiency and accuracy.

Conclusion

Implementing 5S effectively requires reliable and durable labelling solutions. Brother’s TZe laminated labels, combined with the user-friendly P-touch Editor software, provide a comprehensive solution that addresses common labelling issues. These tools improve the efficiency and organisation of the workspace and align with Kaizen principles by promoting continuous improvement and operational excellence.

By choosing Brother’s labelling solutions, factories can enhance their 5S implementation, ensuring that their labels remain legible, durable and residue-free, thereby maintaining a clean and efficient working environment. The user-friendly interface and powerful database connectivity of the P-touch Editor make label creation fast and efficient, freeing up valuable time and resources.